Why Are Mechanical Keyboards So Expensive?

The Most Direct Answer Is The Cost. Whether You Can See It Or Not, The Mechanical Keyboard Displayed In Front Of You Is Genuine. As Long As It Is A Slightly Well-known Brand, From The Inside To The Outside, From Top To Bottom, Whether It Is Materials, Workmanship, Quality Inspection, After-sales, Etc., We Strive For Excellence And Strive For Every Product To Meet High Standards.

Next, I Will Analyze For You Why The Price Of Mechanical Keyboards Is Relatively High Among Similar Products.

1.Visible And Invisible Costs

First Of All, If You Want To Know Where The Mechanical Keyboard Is Expensive, You Must Know The Construction Cost Of The Mechanical Keyboard.

From The Inside To The Outside, There Are Pcb Board, Micro Control Unit (mcu), Voltage Regulator (ldo), Memory, Connection Line, Shaft Body, Upper And Lower Shells, And Some Keyboards Have Steel Plates (positioning Plates) And Sound-absorbing Cotton, Key Caps, Etc. The Composition Of The Object (if Incomplete, Welcome To Add), Whether It Is The Keycap And Shell That We Can See And Touch, Or The Invisible Shaft And Pcb Board, Are All Real Costs.

The Keyboard Also Has The Distinction Of Adding A Positioning Plate. The Function Of Ordinary Keyboards With A Positioning Plate Is To Fix The Shaft Body, While The Kemove K61 And Kemove K68 Butterflies Of The Kemove Series Are Designed Without Steel Plates, So That The Structure Without Steel Plates Can Be Fixed. Harder And With Rebound Ability, Which Is Why These Keyboards Have The Purest Feel.

2.Excavation Of The Mold

The Excavation Of New Molds Is Very Expensive For Small Brands. It Is Reported That An Exquisite Mold Will Cost At Least 20,000 Us Dollars. The Processing Needs Are Precise, And It Also Brings Time, Money And Other Costs. The Reason Why Many Mechanical Keyboards Are Similar Is That Many Manufacturers Are Unwilling To Spend Money On Digging New Molds, And Kemove, As A Keyboard Series With Its Own Unique Shape, Spent A Lot Of Money To Develop Its Own Exclusive Molds.

3.Housing Material

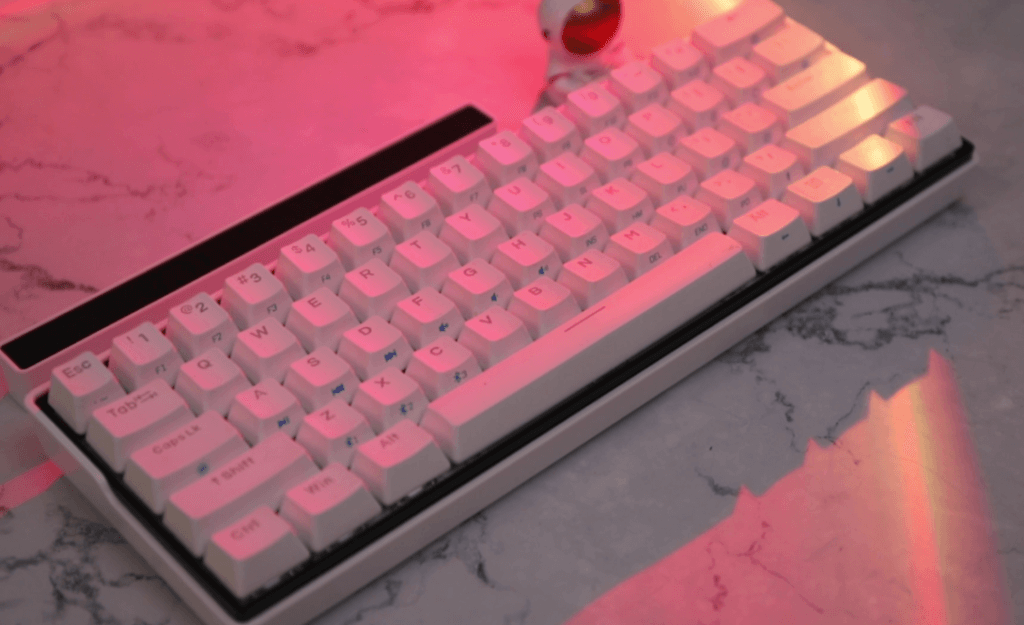

At Present, The Most Widely Used Material For Mechanical Keyboards Is Still Plastic. The Shell Of Kemove K61 Is Made Of Abs Material, While The Aluminum-magnesium Alloy Material Used For Kemove God Of War Series Is Still The Top In The Industry After Being Processed By Cnc Technology. , Which Is The Main Reason Why This Keyboard Looks Exquisite And Beautiful.

4.Keycap Material

As For The Material Of The Keycap, Pbt And Pom Are The Ones With High Cost Requirements, And The Relatively Low-cost Abs Material Is Also Preferred By Many Keyboards At Present. The Pbt Material Used For The Kemove K68 Butterfly Keyboard Has The Advantage Of Being Wear-resistant And Non-greasy. The Character Process Of Engraving Silk Screen Makes The Keycap Characters Not Easy To Wear Off. The Current Material Cost On The Market Is ABS<PBT<POM

5.Shaft Composition

A Switch Body Is Also Composed Of Many Parts, Including The Base, Switch Cap Fixing Card, Spring, Switch Cap, Jumper Wire, Led Light, Contact Metal Sheet, Etc., And As One Of The Core Of The Mechanical Keyboard, The Switch Body, In The Workmanship And Sophistication Cannot Be Ambiguous. It Is Necessary To Ensure That The Production Standards Of Each Switch Are Consistent, So That The Keyboard Can Have A Good Feel.

And There Are Contact Metal Sheets That Improve The Durability Of Use. If The Switch Body Is The Core Of The Mechanical Keyboard, Then The Contact Metal Sheet Is The Core Component Of The Switch Body. Of Course, Under The Premise Of These Guarantees, The Cost Is Inevitable.

6.Welding Of PCB Board

The PCB Board Is Generally The Part Of The Keyboard That Will Not Be Displayed In Front Of The User. There Will Be Chips, Lines, Pads, Components, Etc. On The PCB. The General Difference Is That The Lines Are Different, The Components Are Different, And The Chips Are Different. Ordinary Mechanical Keyboards Generally Use A Single-Layer PCB Board, While Some Are Precisely Fixed The Position Of The Shaft Body To Ensure That A Single Shaft Body Is Accurately Welded To The Designated Pcb Board Position. Multi-layer PCB Boards Are Used, Which Is Also The Main Reason For The High Cost Of Mechanical Keyboards. Reason.

7.The Process Of Quality Inspection

When All The Keyboards Are Assembled, The Keyboard Will Have Quality Inspection And Other Processes In The Follow-up. The Main Processes Include Key Life Test, Electromagnetic Adaptability Standard Test, 65-degree Constant Temperature Test Under Energized State, Percussion Reliability Test, Temperature Test, Drop Testing, Low Temperature Testing, Etc., The Detection Of These Processes Is Also A Major Factor In Cost Increases